Simple Production scheduling Tutorial Template

A manufacturing production schedule is a plan that outlines the specific steps and resources that are required to produce a product. It can help a manufacturer to coordinate the various stages of production, including sourcing materials, assembling parts, and finishing products.

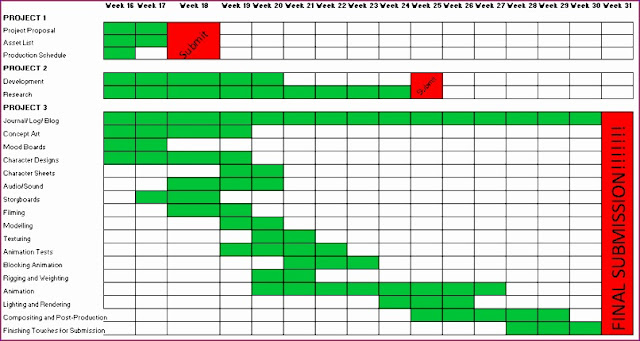

Here is a basic template for a manufacturing production schedule:

1. Product information: This section should include the name of the product, the product number, and any other relevant information such as the quantity being produced and the target completion date.

2. Resource requirements: This section should list the materials and resources that are needed to produce the product, including raw materials, equipment, and labor.

3. Production process: This section should outline the specific steps involved in producing the product, including any sub-processes or subcontracting that may be required.

4. Quality control: This section should outline the quality control measures that will be used to ensure that the finished product meets the required standards.

5. Delivery: This section should outline the delivery schedule for the finished product, including any transportation or storage requirements.

6. Contingency plans: This section should outline any contingency plans that have been put in place in case there are delays or other issues during the production process.

By following a manufacturing production schedule, manufacturers can ensure that the production process runs smoothly and efficiently, and that the finished product meets the required standards.

Comments

Post a Comment